Quality Control Team

KINGDA’s quality control team consists of experienced experts and has built a rigorous quality control program to ensure full compliance with system requirements and product development processes. We adhere to strict standards from product design, inception, and development, to process and packaging.

Our Quality

Children are fragile and they need our protection. When dealing with children's products, KINGDA has a very strict quality control system. We inspect raw materials and assemble products in strict accordance with relevant quality standards and testing criteria.

Instruction Manual & QC Checklist

Before massive production, we’ll make prototypes and pre-production samples. In the process of making them, we’ll know in which parts quality problems are likely to happen or which parts should be paid special attention to in order to avoid quality problems. These points will be included in the instruction manual, which will be used to guide the massive production later. And they’ll also be included in the quality inspector’s checklist for him to perform the quality inspections.

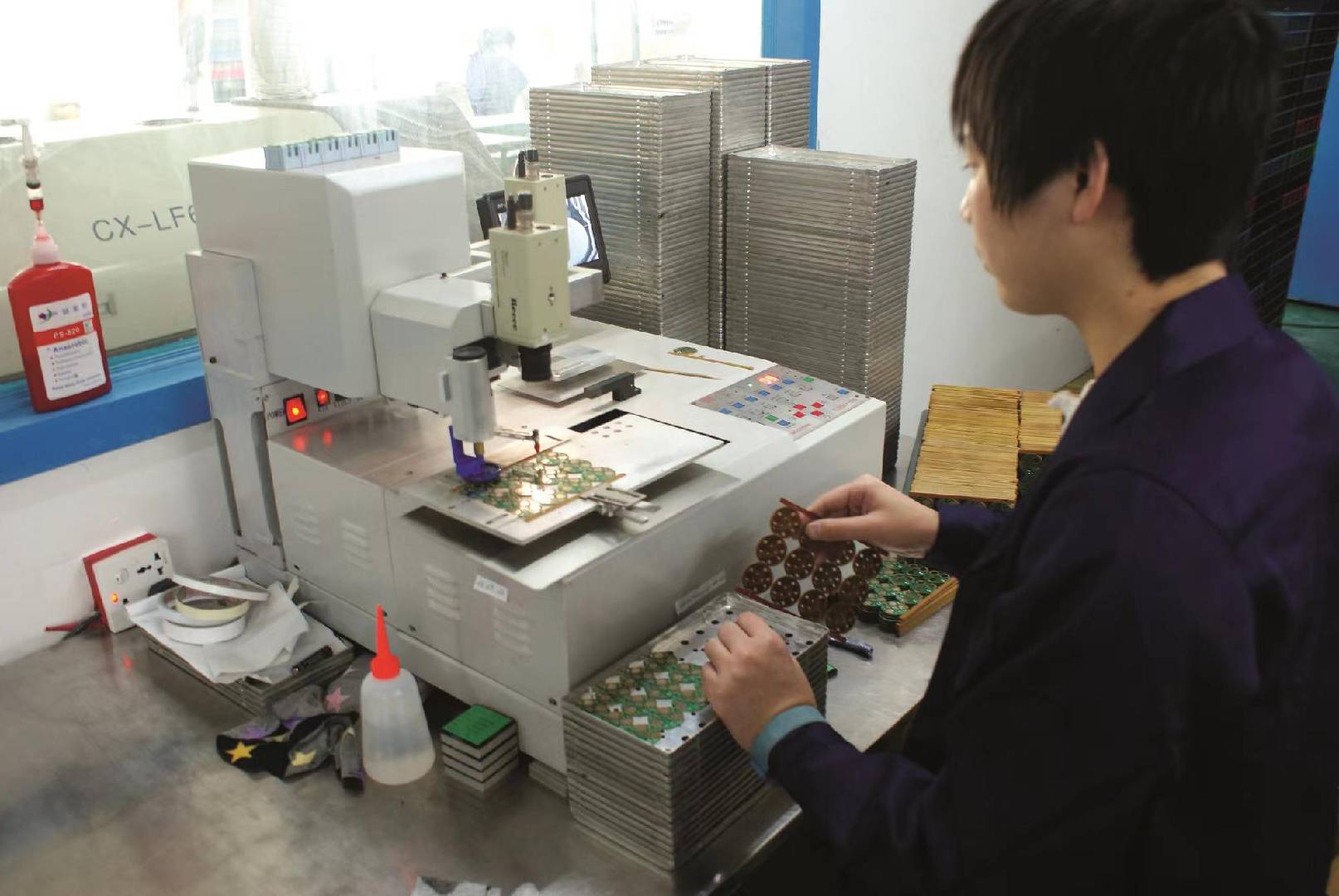

Quality Inspections

Instead of just one quality check at the final assembly stage, KINGDA conducts several quality checks throughout the production process, including molding blanks, painting, printing, and assembly, to ensure that only good quality toys are shipped.

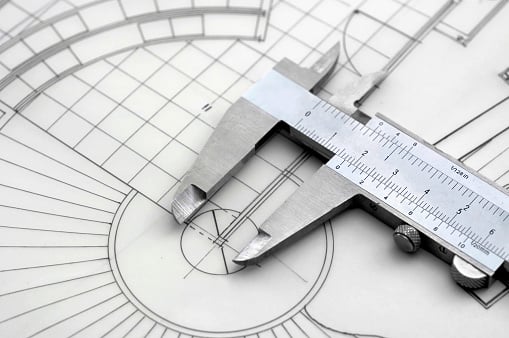

Size Check

Color Check

Moisture Content Test

Dents

Paint Peels Off

Excessive Paint

Burrs

Moisture Content > 15%

Imprint not in the middle

Our Certification

For ten years, KINGDA has been committed to the research, development and exploration of toys. With strict control of product quality, the company has been certified by internationally renowned testing and certification bodies.